New Web Design

After many creative discussions and some wild ideas this is where we finally landed. My goal was to have a web page with a modern and minimalistic touch. Important information should be easy to find and the focus should be on me as a professional and what I do.

My Professional Reputation

The new web is part of a larger effort to reach customers and colleagues in a more professional manner. I hired Per Frykman to find out what my professional reputation was by asking colleagues and clients I worked with what they think are my strengths and weaknesses. The result was overwhelmingly positive, which was a real boost for my self confidence. I must admit that it did feel a bit strange in the beginning presenting the result publicly, this is not so common in Sweden. But hey, when looking for a new job you give references to your future employers and my professional reputation is actually a condensed ten-person reference!

Photos

I also had some new photos taken by a professional photographer. Armand Dommer usually has clients that are younger and better looking than me but I think he did a great job with the material he had this time!

What´s With the Blogging?

The last three months the web has been under development so I have intentionally not wanted to update or change anything. However I have been very busy reading and writing.

New Learnings

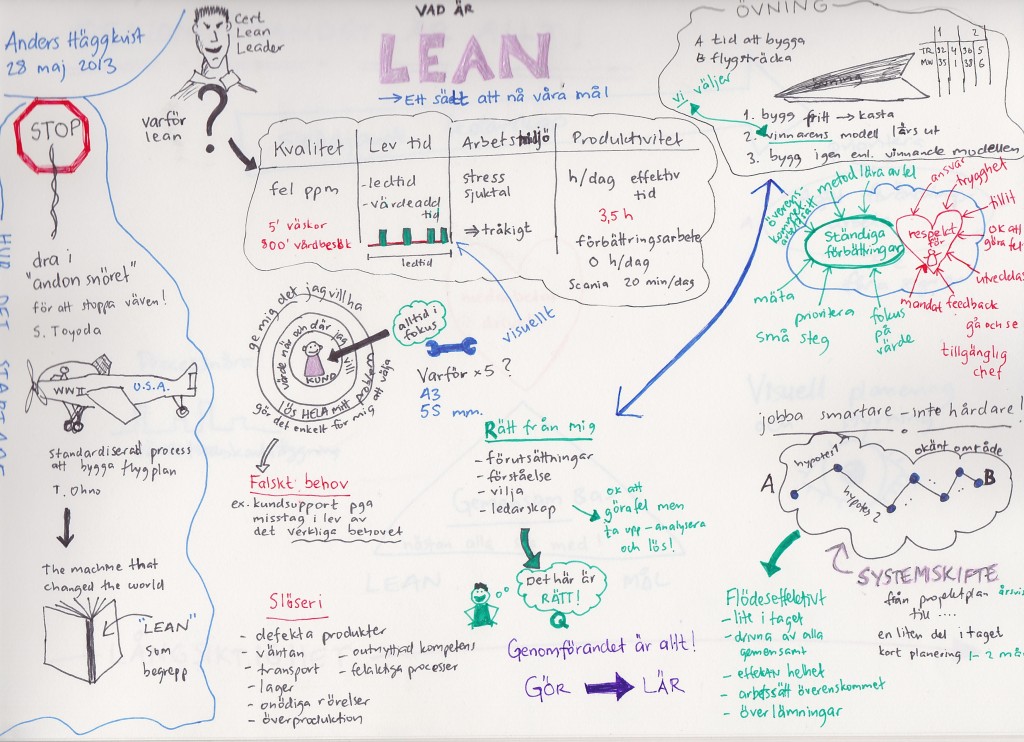

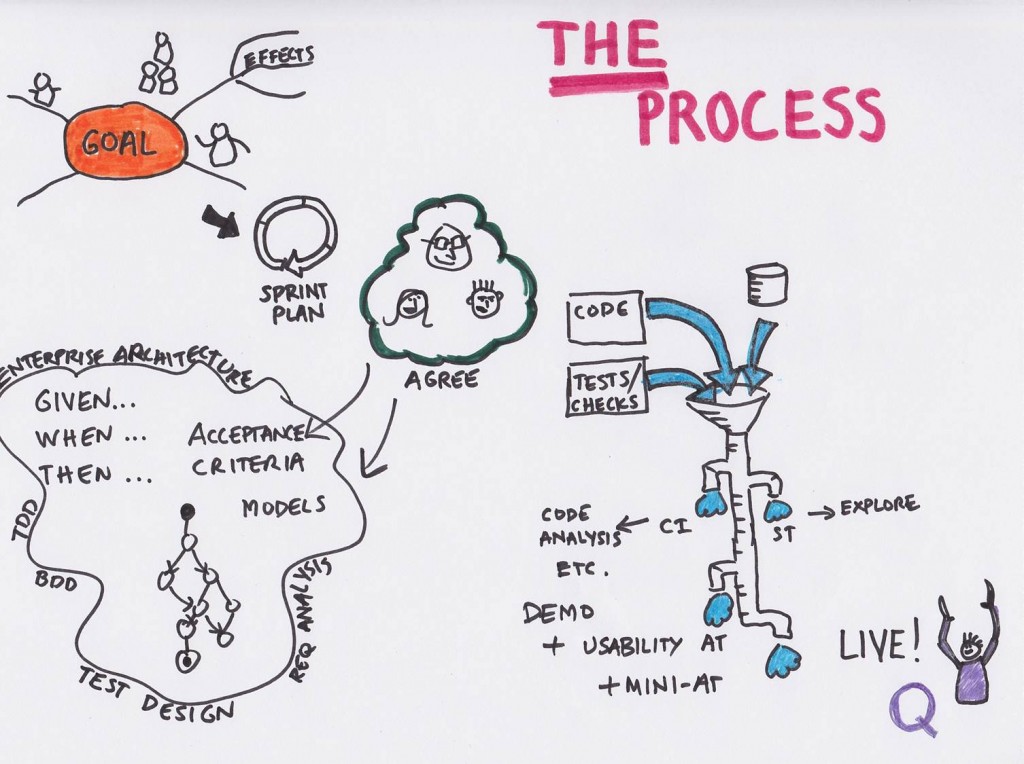

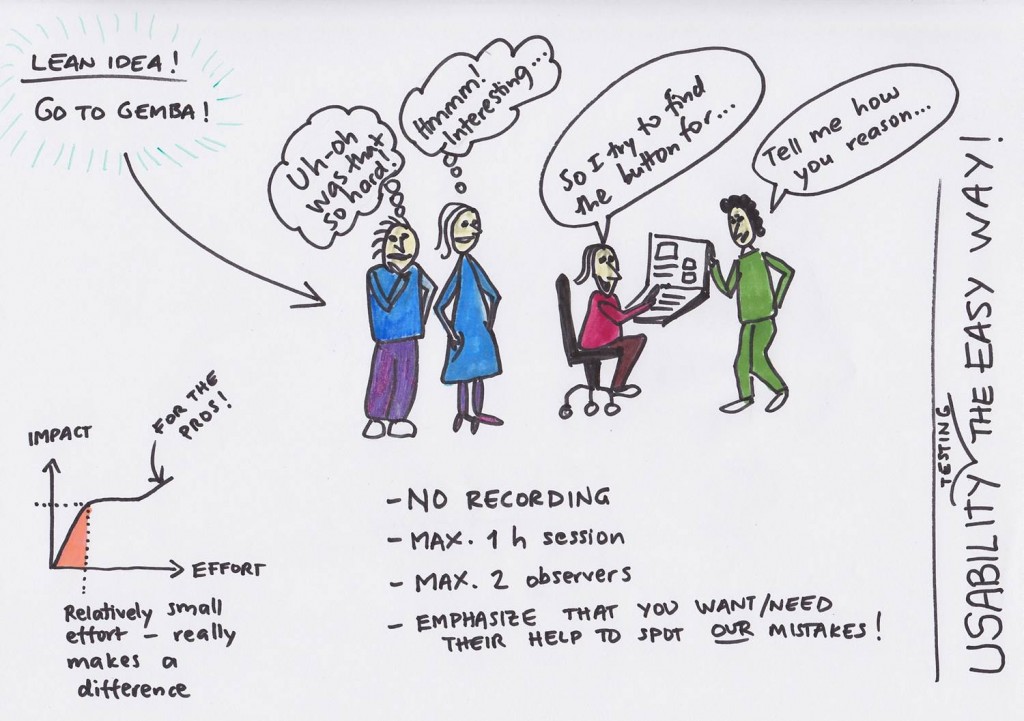

I have been digging deep into visual problem solving reading the works by Mike Rohde, Becky Agerbeck, Dan Roam, David Sibbet, Lee Lefever and bikablo dictionaries. Test design modelling goes right along the same track of visualizing problems in order to analyse and increase collaboration.

In November I will be giving a full day tutorial at EuroSTAR and I really wanted to update the material with all the new ideas I have. Creating the material included not only new content and new slides but a 50 page paper on the subject! This paper is submitted for the EuroSTAR contest besides being material for the tutorial. The paper will be available as an e-book in November.

I have also written a shorter article on the same subject in Swedish. This is part of a book that will be published in November by TestZonen.

The Lean Effort I Started?

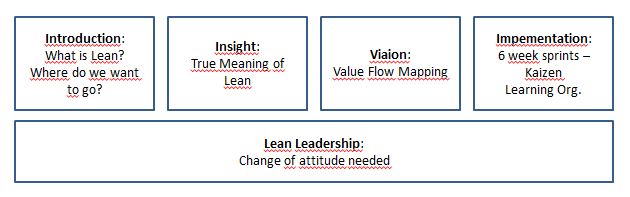

Since last blogging I have participated in a value flow mapping workshop taking notes and analysing the workflow. This was an enlightening day on how these workshops are conducted but I will not be able to share any details due to confidentiality agreements. My job was paying attention to the group, keeping my mouth shut, thinking hard and documenting. Later I discussed my findings in detail with the workshop leader.

The Toyota Kata book is the next item on my reading list for Lean. Problem is that there are so many interesting books on other subjects I still have not read.

What About Work?

I have a part time assignment testing a web application which is planned to end around Christmas. Besides that I give classes in testing.

I will be participating in a management consulting effort done by my colleague Mattias Nordin and am discussing a lot around enterprise architecture with my friend, teacher and guru Peter Tallungs. I want to increase my skills in these areas and what’s better than learning from the pro’s in real situations!

As of right now I have openings for new assignments starting January next year.

[social icon="twitter" url="http://www.twitter.com" target="_blank"]